Sustainability

Extending Service Life for a Life-Cycle Cost Advantage

The PlusTi™ family of smog-eating-road penetrants reduce the life-cycle costs of asphalt and concrete surfaces, doubling the service life of roadways, runways, bridges and related infrastructure. These innovative solutions transform roadways into resilient, sustainable pavements in three ways:

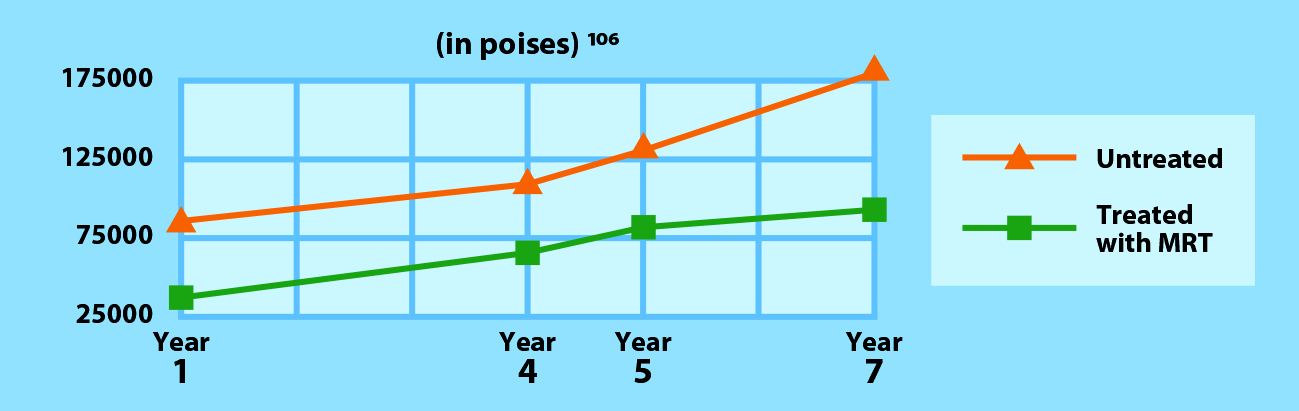

1 PlusTi™ rejuvenator / sealer 1 and PlusTi™ longitudinal joint stabilizer 2 use Maltene Replacement Technology (MRT), which has been lab tested and field proven for nearly half a century, to return to asphalt pavements the maltene fractions lost during asphalt production and subsequent oxidation. The UV-protective surface left behind also inhibits moisture intrusion for extended service life.

PROVEN: MRT Extends Service Life

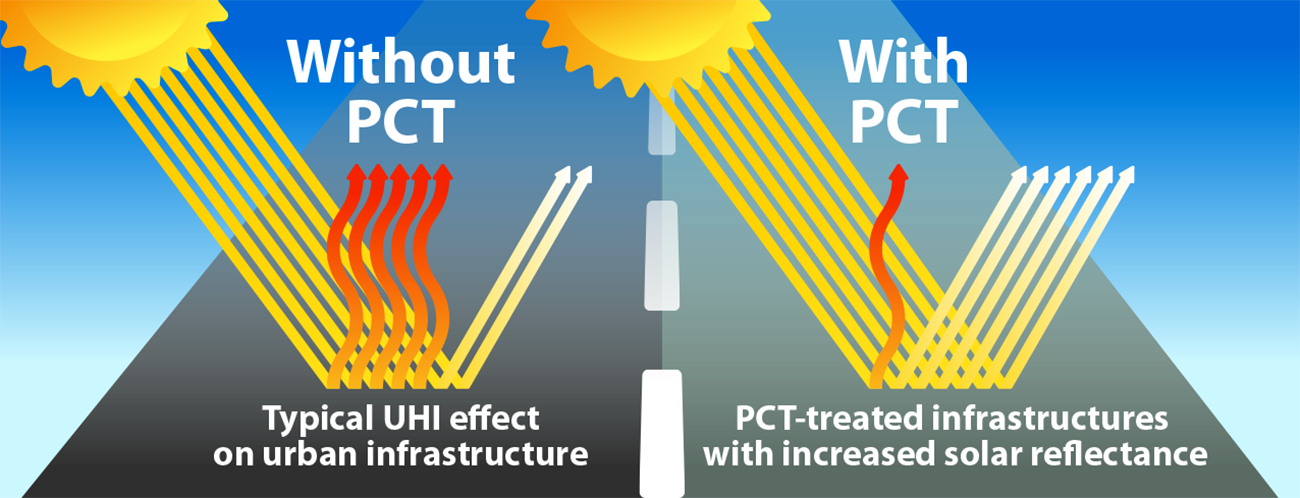

2 The service life of the entire suite of PlusTi™ solutions for asphalt and concrete surfaces is further extended through the use of Photo Catalytic Technology (PCT) that effectively reduces surface temperatures. Simply put, heat shortens pavement life.

PROVEN: Cool Substrates Extend Service Life

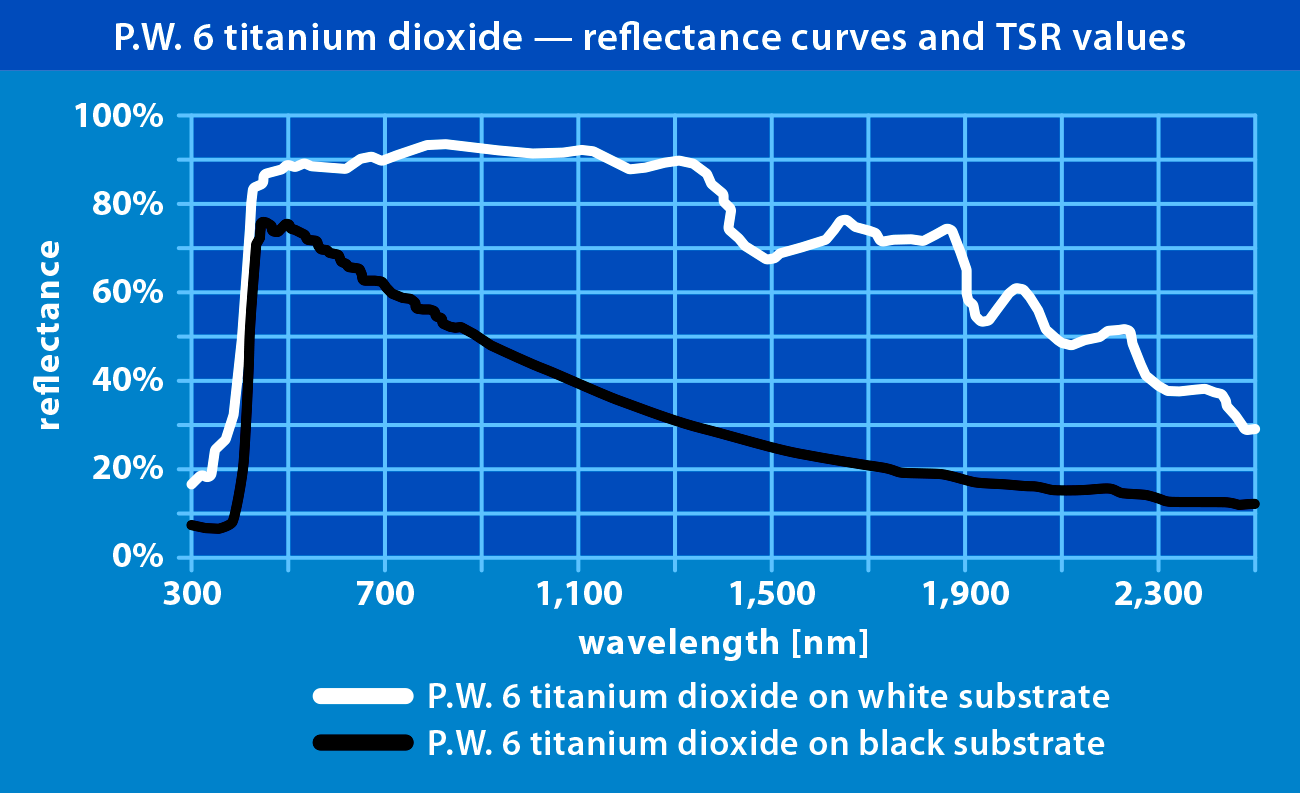

PROVEN: TiO2 Improves Solar Reflectance, Mitigating UHI

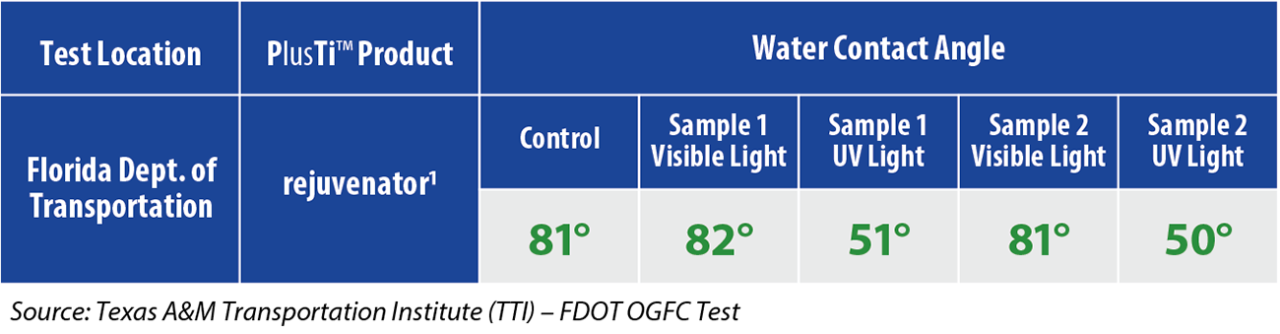

3 PlusTi rejuvenator, longitudinal joint stabilizer all-purpose penetrant, and hardener / sealer are also super-hydrophilic, which translates into accelerated water dispersion across the substrate surface.