Asphalt Restoration Solutions: What to Know

Category: Blog Articles By: Chris Evers

Introduction

People often ask me, “Chris what can I do to make the asphalt roads in our community last longer?” I reply with all of the standard answers formulated over my 25 years in the industry. As I was starting to write this blog, I thought of my car owner’s manual (including some normal disclaimers, service alerts/warnings and best practices). Now admittedly most folks don’t pull out their owner’s manual until there is a problem – but all would agree it is more useful to read the manual before a problem occurs!

For this article, I’d like to focus on the Restoration Chapter of an imaginary Asphalt Pavement Owner’s Manual. Being aware of asphalt restoration solutions is critical to the proper care of any asset, and roads are no exception. I imagine the chapter would read something like this.

Asphalt Pavement Owner’s Manual

SERVICE ALERT

If you choose not to perform standard preventive maintenance on your pavement it could result in expensive repairs down the road (pun intended).

Best Practice Maintenance Guidelines

Best practices for assets whether they are cars, houses or roads, always include specific routine maintenance to be performed “at the right time.” To ensure the longevity of your asphalt roadway, and thereby the lowest cost of ownership for this asset, follow these best practice guidelines.

Day One

Congrats, you just pulled your pavement off the lot!

(2) Day 300 to Day 330

SERVICE ALERT

Your typical one-year warranty from the asphalt paving contractor will soon expire. Since the quality of resurfacing projects is very application dependent, inspecting the pavement at around 10 to 11 months is key to catching any possible workmanship or material defects. Such problems may have been overlooked at project completion or may be just now appearing.

Your pavement engineer, project manager or consulting engineer should conduct a warranty inspection, looking for any surface defects, substantial failures, excessive cracking or loss of fine aggregate – anything indicative of pavement issues. If they observe something troubling, schedule a site visit with the contractor who performed the work and make certain they remedy any problems before your warranty expires.

You may have noticed your roadways are dark gray in color – not the jet-black roads of earlier times. That’s not a bad thing.

SAFETY ALERT, WARNING!

Agencies and private communities should fight the urge to paint their roads black with the many coal tar sealants on the market. Coal tar sealants pose an environmental and health hazard. They retain heat that can accelerate UV damage to your roadways. They can also burn a dog’s paws in minutes. Always ask for the Safety Data Sheet of any material prior to allowing a contractor to apply it to your roads.

Check out the February, 2013 issue of the APWA Reporter article “You’re Standing on it! Coal-tar-based pavement sealcoat and environmental and human health,“ for more details on coal tar products.

(3) Day 366 to Day 1096

Your pavement is now ready for an oil change – use only approved formulations. The asphalt pavement has been oxidizing slowly in the bright sun over the last one to three years. Depending on your climate zone, it may also have been subjected to the freeze/thaw cycle that is torture to pavements.

Always perform your first asphalt restoration from one to three years after your road was constructed or resurfaced. For asphalt pavement, the equivalent of your car’s “approved motor oil” is a maltene-replacement formulation commonly referred to as Maltene Replacement Technology (MRT). MRT returns to your pavement the light ends that were in the original asphalt material and were subsequently lost, first during asphalt production, and later through oxidation.

Just like the breakdown of motor oil in your engine, the asphalt binder that holds the road together becomes old and brittle when left untreated. By spray applying an asphalt rejuvenator made from the very same component that has been depleted, you will extend the life of your community’s roads by five years or more for each treatment.

Typically, MRT can be used two or three times during a pavement’s lifecycle, further increasing the return on your pavement investment. Recommended intervals are dependent upon road conditions, but a typical roadway may be MRT treated, for example, in years two, seven and 12.

Where to Go for Asphalt Restoration Service

Always trust the restoration of your roads to experts. Ask for and review references from other cities and counties before making a decision on who can be trusted to work on your roads.

Unfortunately, unlike automobile owner’s manuals, which typically suggest using your neighborhood car dealership for routine maintenance, asphalt paving contractors do not perform early preventive maintenance on the roads they resurface, so we are unable to include such recommendations in this Asphalt Pavement Owner’s Manual.

Real Science Produces Real Results

Since our imaginary manual is unable to help us identify the right applicator for expert asphalt restoration, I will conclude this article with some information that can help you make an informed decision.

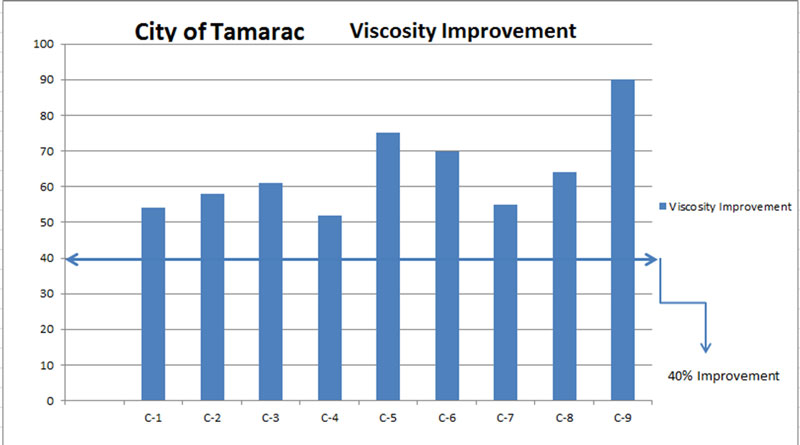

People believe what they can see. Does the company you trust to service your asphalt pavement have test results backed up by real science? If you used a maltene-based rejuvenator, the contractor should be able to provide you with testing demonstrating how much the restoration process will soften the binder and add life back to your road. By reviewing the test results they have achieved on projects with large public works agencies, you can gain confidence that a specific applicator will properly service your asphalt. Results should show long-term effectiveness over years of testing, not merely short term softening of the asphalt binder, which could be indicative of solvent use.

If yours is a larger project, it may even be possible to conduct testing on your own rejuvenation project, providing you with hard evidence that your dollars have been well spent. Results should look a lot like the graph below, which shows a reduction in the viscosity (or hardness) of the asphalt binder treated vs. untreated. A properly applied MRT should produce similar results. Of course, as with cars, the results will “vary by model” – meaning that the quality and age of the asphalt roadway, and external factors such as “how hard you drive it,” will affect outcomes.

Getting Your Money’s Worth with Asphalt Restoration

If you ask your neighbor what they think of their car, you’re likely to hear some comment about how well the car has held up and what the resale value is. Those two things are interconnected. If the neighbor took good care of the vehicle and did not put excessive mileage (aging) on it, most likely it has remained in sound condition, In that case, it would be considered a sound investment. Return On Investment (ROI) is a popular performance measure used in all corners of the economic world. Its popularity is as easy to understand. Its formula simply takes the ROI (which in this case would be the dollars saved by extending the roadway’s service life), subtracting the cost of investment, and then dividing the total by the cost of the investment.

By way of an example:

- If the original project cost was $235,000, and you apply a two percent inflation rate over the 20-year service life, then the replacement cost in 2039 would be $349,198. If you divide that total by 20 years, you will get $17,460 as the required annual reserve funding needed to afford replacement.

- If you take the treatment cost, similarly, adjusted for inflation, the total preservation cost for treatment one would be $18,735, and for treatment two would be $20,279, for a total investment of $39,014.

- Conservatively, the original 20-year service life has now been extended for five years (first treatment) and an additional four years (second treatment) – which means the service life has increased from 20 to 29 years.

- New Asphalt Replacement Cost: $352,007

- New reserve funding required: $12,138/year

- Total Savings: $154,330

- ROI: 296%

This gives you a total savings of $154,330. Your total preservation investment of $39,014 divided by the total cost of restoration ($39,014) gives you a 296% ROI!

Conclusion

There is no better way to get the most out of your roads than to preserve and restore them. Good roads cost money, but bad roads cost more.To get the highest ROI possible on your asphalt roads, the experts will tell you to use what hundreds of cities and counties around the country have counted on for decades to preserve their roads. Maltene Replacement Technology, aka asphalt rejuvenation is the best way to keep your good roads good.

Would you like to learn more? Contact us today or call 800-333-6309.