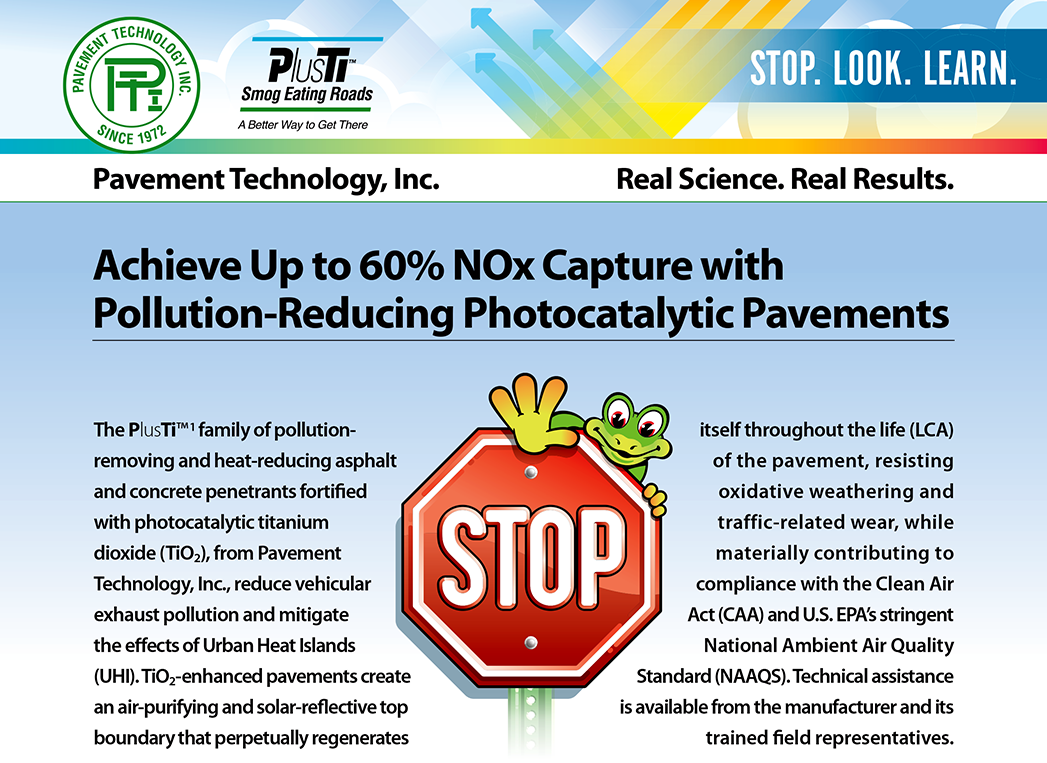

Smog Eating Roads

Research into the viability of photocatalytic pavements began in Japan in the early 1970s, and has progressed throughout Europe in more recent decades. In North America, the commercial use of titanium dioxide (TiO2) to transform asphalt and concrete pavements into pollution-reducing, heat-reducing photocatalytic pavements became economically feasible with the introduction of PTI’s family of PlusTi™ Photo Catalytic Technology (PCT) solutions.

A.R.A.-1 Ti® pollution-reducing asphalt rejuvenator combines PCT with Maltene Replacement Technology (MRT) to extend roadway life while mitigating Urban Heat Island effect (HIE), reducing vehicle-related pollutants and dispersing surface moisture more rapidly.

Advancement in this area is continuing today with PTI’s progressive introduction of a variety of TiO2-enhanced PlusTi™ pollution-reducing road rejuvenation and preservation products, currently including JOINTBONDTi® longitudinal joint stabilizer, Litho1000Ti® concrete sealer/hardener, and a Ti-intro CME® titanium-dioxide penetrant for all transportation-related infrastructure. Inquiries welcome.

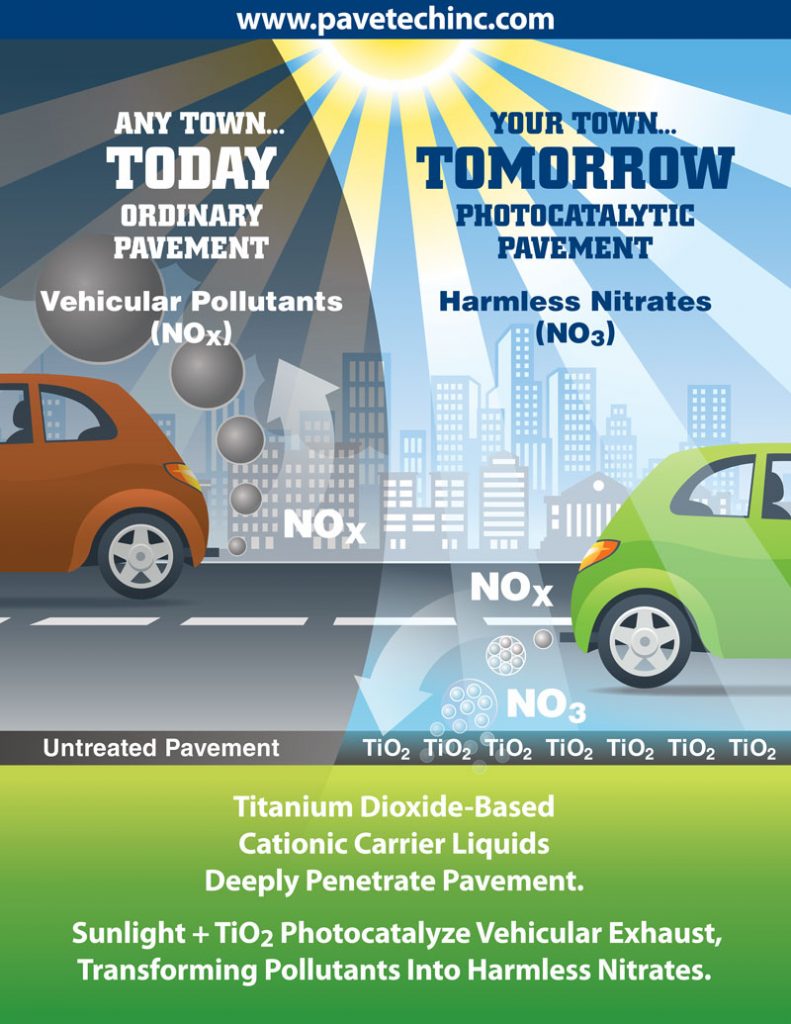

How It Works

It has long been known TiO2 creates hydroxyl radicals and superoxides when exposed to UV light, which, as they oxidize, naturally decompose any surrounding atmospheric nitrous dioxides (NO2). This photodegradation process transforms these pollution-causing particulates into water-soluble sulfates (nitrates), which are then washed away from the pavement surface when it rains.

“The combination of pollution-reducing Photo Catalytic Technology and Maltene Replacement Technology pavement rejuvenation will be a game changer for our industry.”

Colin Durante, Founder and President, PTI

The Development Process

PTI’s research and development team worked closely with a leading U.S. based university to determine how best to ensure deep penetration of a titanium-dioxide-based formulation. Varying carrier liquid component ratios were tested to identify the ideal formulation for optimizing performance of the chemistry, with the goal of sustaining the smog eating effect as concrete and asphalt pavements inevitably age and wear.

Humidity, temperature, flow rates and method applications are only a handful of the many factors tested and evaluated in order to develop a product capable of providing a sustainable photocatalytic self-cleaning surface that removes nitrogen oxides (NOx), volatile organic compounds and other pollutants introduced into the atmosphere through vehicular exhaust.

The resulting air-purifying surface perpetually regenerates itself throughout the life of the pavement, contributing to compliance with U.S. EPA’s stringent new National Ambient Air Quality Standard (NAAQS).

PTI informally introduced its PlusTi™ family of pollution-reducing technologies during EarthX 2019.

Laboratory and Field Proven

Durability and Performance of Titanium Dioxide in Photocatalytic Pavements

The “Laboratory Investigation of the Effect of TiO2 Topical Treatments on Concrete and Asphalt Samples,” conducted by Texas A&M Transportation Institute, examines the effectiveness of PTI’s titanium-dioxide-enhanced chemistries, and is now complete. This study offers a general overview of the application of titanium dioxide (TiO2) to concrete and asphalt surfaces to impart air pollution remediation properties. It is available upon request.