Got Maltenes?

When it comes to asphalt pavement preservation, the magic is in the maltenes.

The goal of these pages is to explain the naturally resilient chemistry Pavement Technology refers to as Maltene Replacement Technology (MRT), and its demonstrative benefits in comparison with alternative methodologies for preserving asphalt pavements. Use the links below to delve more deeply into each concept discussed or use the form on this page to request a comprehensive white paper on this topic.

Check out the Spring 2020 issue of the Pavement Preservation Journal for the more information on MRT.

Sustainable Asphalt Pavements: The Science Behind Maltene Replacement Technology

In recent years, there has been no shortage of confusion (and some intentional misdirection) in the asphalt pavement preservation marketplace regarding the definition and understanding of maltenes and the role they play in rehabilitating and extending the life of asphalt roadways. Let’s clear up the confusion.

The magic is in the maltenes [VIDEO]

Watch the video to learn more about asphalt, one of Mother Nature’s greatest inventions. Learn about maltenes and Maltene Replacement Technology (MRT) and our efforts to combat pollution. Or, get more insights about maltenes and real science.

ASPHALT ROAD BIO-BASED REJUVENATORS – FUNCTIONALITY REVIEW

Category: Blog Articles By: Michael Durante

In recent years, there has been no shortage of confusion (and some intentional misdirection) in the asphalt pavement preservation marketplace in relation to the definition and understanding of maltenes and the role they play in rehabilitating and extending the life of asphalt roadways. For a clear understanding of the natural, resilient chemistry Pavement Technology calls Maltene Replacement Technology, and its demonstrative benefits, especially in comparison with alternative methodologies for preserving asphalt pavements, we refer you to The Science of Maltene Replacement Technology for Sustainable Asphalts.

Here, the purpose is to dig deeper into the chemical compatibility of so-called “bio-based rejuvenators” with asphalt pavements.

Bio-based Product Compatibility Questions

Since their sudden and recent arrival to the pavement preservation market, bio-based products have gained a fair amount of attention yet remain a bit of a mystery to many practitioners.

There is good reason for them to be reluctant to identify the constituent components of these largely agricultural-derived compounds and to hide behind “trade secret” loopholes when asked to explain exactly how these composites chemically interact with asphalts.

Asphalt binder has but two molecular components — maltenes and asphaltene. Together, they present a specific, chemically dependent molecular structure that functions in a continuum (chemical matrix) where the maltenes and asphaltene are separately identifiable phases of a singular colloidal solution. Certain of the maltenes provide fluidity and ductility; asphaltene is the filler. Any imbalance or separation of the two embodiments is what causes asphalts to age and fail. This has been “settled science” for nearly 60 years.

A genuine rejuvenator is any compound that restores the proper chemical balance between maltenes and asphaltene. How a compound chemically reacts with asphalt binder is critical — and Maltene Replacement Technology is the only proven method for restoring chemical balance in asphalts.

Agricultural-based products do not contain maltenes. Maltenes are only found in petroleum. They are complex, dense hydrocarbon molecules which naturally complement the chemistry of asphaltene in a maltene-asphaltene matrix, as previously described.

Agricultural oil derivatives, by contrast, are not molecularly synergistic with multicomplex (polycyclic) petroleums. They are monocyclic, ultra-light and volatile (unstable), with rapid evaporation rates. Most are categorized as having varying levels of volatile organic compounds (VOC and SVOC) that are considered damaging to the environment by climate scientists. In addition, these compounds, as solvents, react with asphalts entirely differently than do petroleum maltenes.

The comparative physiochemical responses at play are equally disparate. They are chemical flux in the case of maltenes and chemical flocculation (floc) with agricultural-derived solvent compounds. Both types may have the initial effect of reducing the viscosity and penetration value of asphalt binder. However, only the maltenes have been proven to do so by promoting improved and restored natural chemical flow within the asphalt binder matrix.

Agriculturally derived solvents result from the reaction between a vegetable oil and an acid. In contrast with maltenes, a bio-solvent’s chemical structure separates asphalt binder components through dissolution (dissolving), leaving the asphalt binder further depleted of the already depleted hydrating maltenes in aging pavement. The result is further phase separation in the binder, accelerating the embrittlement of aging asphalts treated with these de facto agricultural-based solvents, i.e., bio-solvents. In short, bio-solvents act as de-stabilizing reagents to the asphalt binder, which is the opposite of rejuvenation.

Unlike natural maltene-based rejuvenators, bio-solvents require a drastic chemical conversion (radicalization) of vegetable oil (animal fat) into fatty acid methyl esters (FAMEs) in order to achieve reaction with asphalts. This reaction is chemical dissolution and is specifically engineered to disrupt flux by chemically separating the components of the binder structure, thereby promoting flocculation, which literally means “to flake.” So, bio-solvents are “flocculants” that dry out a compound, dissolving the natural, sustainable fluidity-promoting components by separating and exposing the remaining maltenes in aged asphalts to accelerated oxidation.

In industries such as cosmetics, these solvents commonly are referred to as “drying oils.” And this is exactly how a bio-solvent interacts with asphalts. In the computer chip (semiconductor) industry, these compounds are called “flux removers.” And historically in the oil drilling and paving industries, they are used as asphalt releasers. They make very efficient industrial-strength cleaners, degreasers and asphalt-release agents.

The key measurement for chemical flux is time-tested performance, albeit a molecular spectrometer can also be used in the modern age to witness flux. Maltene-rich rejuvenators have been demonstrating their efficacy in over a half a century of exhaustive field applications, including side-but-side comparisons and lab testing. In contrast, the testing performed on bio-solvents uses an entirely different methodology.

Bio-based Product Testing – “Kb Value”

The key measurement for solvents, including bio-solvents, is Kauri-butanol value (“Kb value”). This test measures the amount of time it takes a given solvent to dissolve the natural rubber from a New Zealand kauri tree. The base solvent is the common sugar-derived alcohol known as butanol. The test is standardized under ASTM D1133-13 1 1. The higher a product’s Kb value, the higher its solvency power. ASTM D1133-13 is found on the Safety Data Sheets (SDS) and/or performance specifications of all solvents. Yet this test appears never to be performed or acknowledged on the bio-solvents marketed as so-called “bio-based rejuvenators.”

All bio-solvents principally come in the form of alcohols and acids. Several of the bio-based products we’ve seen promoted in the pavement preservation marketplace are simple hydrocarbon-based solvents combined with some “reacted” fatty-acid-based solvent composition; others are nearly pure FAMEs.

The hydro carbonic solvent in these products typically is d-limonene, a terpene-based solvent in the same family as turpentine, which is derived from pine tree sap. D-limonene comes from the distillation of citrus fruit rinds. These molecularly identical bio-solvents are very powerful and are often used to dissolve asphalts.

The fatty-acid component (carboxylic solvent) in these products is a methyl ester derived from one of a variety of seeds, beans or grains, such as soybeans, corn, linseed, etc. For those products using FAMEs as the reacting agent, it should be noted that FAMEs are more commonly referred to as biodiesel fuels, aka bio-fuels.

Neither hydrocarbon solvents nor the “activated” methyl esters of vegetable oils are flux providers. They are ‘flux removers,” as previously described, and are often labeled as such commercially and sold as industrial-strength solvents.

Here are the Kb values of some common natural and agriculture-derived solvents:

| Chemical Name | Derived from | Kb Value |

| Methyl Linoleate | Linseed Oil | 58 |

| Methyl Soyate | Soybean | 59 |

| D-limonene | Citrus | 68 |

| Corn Ethanol | Corn | 68 |

| Turpentine | Pine Tree | 68 |

| Octane | Petroleum | 27 |

| Hexane | Petroleum | 31 |

| Kerosene | Petroleum | 33 |

The names or synonyms used on SDS can sometimes be confusing, even misleading. The technical name for soy-derived biodiesel fuel is methyl soyate, methanol being the simplest natural alcohol. Corn-based biofuel is also called corn ethanol. The chemical names commonly used for radicalized linseed oil (flaxseed) are linoleic acid or methyl linoleate.

Agricultural-based bio-solvents are measurably more powerful in terms of solvency than are known petroleum diluents such as kerosene and octane. All can be used to cut or dissolve petroleum compounds and many are used commercially to that sole purpose. Yet despite a solvent’s mere ability to “soften” asphalts through dissolution (as a high Kb value indicates), no one would suggest using turpentine, kerosene etc. as an “asphalt rejuvenator.”

Full, factual chemical disclosers on any proposed “asphalt rejuvenator’s” SDS or performance specification would go a long way towards resolving the confusion that currently exists in the asphalt pavement market.

NCAT Warns of Disparate Chemistries

In a recent study by the National Center for Asphalt Technology (NCAT) at Auburn University, NCAT researchers tested several chemical compounds marketed as “rejuvenators” for reactivity with aged asphalt pavements. NCAT determined that the bio-based products they evaluated chemically softened the asphalt through “lowering the viscosity of the continuous solvent phase” 2 2 [of the binder matrix]. Stated simply: the chemical reaction between bio-based products and asphalt exacerbates the separation of maltenes and asphaltene that is already in progress due to oxidation of the aging asphalt pavement. Prominent asphalt chemist Dr. Gayle King refers to this as “diluting the maltene phase.” 3 3 Such dilution damages the integrity of the asphalt binder, leading to accelerated pavement aging.

NCAT further qualified their

asphalt rejuvenator study with the following warning:

For optimal restoration of the aged asphalt binder, consideration should be given to the chemical composition of the rejuvenator rather than just its capacity to reduce the viscosity of the aged binder.” 4 4

As NCAT pointed out, bio-solvents simply trigger the process of dissolving the already depleted maltenes left in the aged asphalt binder, rather than replenishing them with the genuine restorative chemistry known as Maltene Replacement Technology.

Ask the Right Question(s)

Identifying the underlying chemicals represented by bio-based products can be as simple as reviewing their SDS, which should provide complete and accurate Chemical Abstracts Service (CAS) number(s) and common names and synonyms for all or most of the product’s constituent components. The simplest way to make certain you’re not introducing a deleterious compound to an asphalt substrate is to request a current and complete SDS and check the Kb value of the substance you’re contemplating using. In addition, always test new products in the field over multiple periods to ensure asphalt compatibility and performance over time. The proof is in the pavement!

Maltene Insights: Real Science

According to the American Chemical Society, in an

article published November 22, 1999, maltenes are one of two major categories of compounds that make up asphalt, the other being asphaltenes.

In recent years, a number of manufacturers have incorrectly used the word “maltenes” to mean whatever they want it to mean. When we use the term at PTI, we are using it as originally defined by our industry. For a more comprehensive understanding of the roles played by asphaltenes and maltenes in paving asphalt, The Asphalt Institute’s Educational Series No. 8 publication is available for a modest cost directly from the Institute by calling 1-859-299-4960.

Simply put, maltenes are the sticky oily components only found in petroleum and characterized by their solubility and low molecular weight. In contrast, the petroleum components known as asphaltenes are insoluble and are higher in molecular weight.

Pavement deterioration is directly linked to the loss of petroleum maltenes. The ability to restore to aging asphalt the original maltene content is the hallmark of the asphalt treatments we manufacture and distribute.

Why it Matters

Back in the early 1960s, Dr. Fritz Rostler, while working for the Golden Bear Oil Company, discovered the origin of asphalt pavement degeneration. By separating the components of asphalt in laboratory conditions, Dr. Rostler determined that asphalt’s soluble, more reactive components, known as maltenes, degrade when exposed to the heat used in processing asphalt-based formulations, and then further degrade as asphalt is exposed to the oxidizing effects of UV in field installations.

In collaboration with Golden Bear’s Richard White, Dr. Rostler set about developing a technology that would literally restore the petroleum maltenes to aging asphalt, rejuvenating its pliability and resilience, thereby significantly improving pavement durability and extending pavement life cycle.

Genuine petroleum Maltene Replacement Technology (MRT) remains the most sustainable process currently available for optimizing the service life of asphalt pavement.

What’s Next?

PTI’s depth of real-world experience applying our industry’s original Maltene Replacement T

These include JOINTBOND® longitudinal joint stabilizer, JOINTBONDTi® pollution- and heat-reducing longitudinal joint stabilizer, A.R.A.-1 Ti®

We are in the process of extending our current product line of titanium-oxide-enriched materials with the goal of eventually transforming a significant portion of America’s roadways into photocatalytic pavement capable of proactively reducing air pollution related to vehicle exhaust emissions.

Prove It

All of the products we make and most of the products we sell have extensive field test data available to validate our performance claims, much of it independently conducted by our public agency customers. Your local PTI service representative can share with you data from communities in your region, including before and after photographic documentation, to help you present the case for proven PTI technologies.

Read more about The Science of Pavement Preservation in real world applications.

Read more about Maltene Replacement Technology and Green House Gas (GHG) Mitigation.

Asphalt Surface Treatment Methods to Extend Pavement Life

Category: Blog Articles By: David Helm

If your community has spent a fortune over the years rehabilitating roads, you understand the work involved in creating and bringing road improvement projects to completion. Much of the heavy lifting is done in planning, from finding the funding to specifying a project’s parameters. Then, finally, the new ribbon of asphalt is installed and construction is completed! Our transportation system roadways are among the most valuable assets we manage, including asphalt surface treatment choices.

When construction ends destruction begins

New, smooth paving jobs begin to age the day they are laid. In fact, this deterioration begins even before the asphalt hits the road, due to the heat of manufacturing. Then, overtime, oxidation and moisture intrusion accelerate aging of the road resulting in raveling, surface roughness and pot holes.

What you can do about it

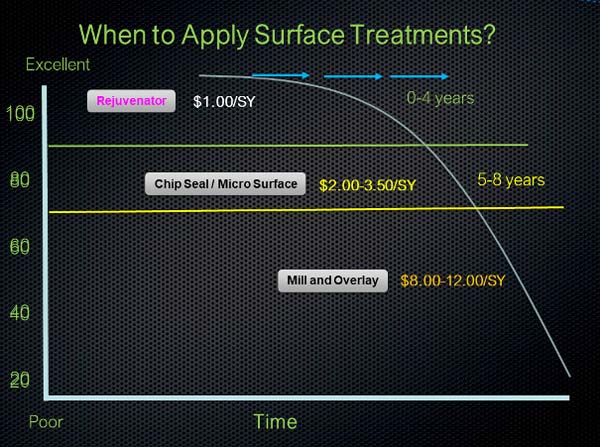

There are several affordable asphalt surface treatment techniques to preserve and extend the life of your capital improvement projects. When applied at the right time, you can maintain a high-quality standard and lower your life-cycle cost. A stitch in time saves nine.

This illustration shows common surface treatment types, costs and when to apply them:

Surface Treatment Descriptions

Asphalt rejuvenator

A good first step in pavement preservation is asphalt rejuvenation. This treatment is applied at the top of the curve. It can be done as part of the new construction or soon after construction. The basic function of a rejuvenator is to preserve durability and seal the surface. It prolongs the time before more expensive processes are needed.

Asphalt rejuvenation replaces asphalt components known as petroleum maltenes. These are the constituents of the asphalt cement that are initially lost in the heat of manufacture, and then continue to dissipate due to weathering and oxidation over time.

Maltenes are the natural components of asphalt that create fluidity and cohesion. One could say maltenes are a bit like glue, giving asphalt its adhesion properties.

The Advantages of Asphalt Rejuvenation Treatment

- Seals the surface form moisture

- Extends the period during which critical asphalt hardening occurs

- Enables traffic to reopen in minutes

- Preserves existing striping

- Keeps roads smooth and in good condition longer

- Extends road life from four to five years

- Requires only a low-cost investment to implement

Chip Seal

Chip sealing is a spray-applied asphalt emulsion, followed by a surfacing of crushed aggregate. Historically, this method has more than a century of use. It can be customized to different road conditions and types of applications. For example, a single-seal coat or a double-seal coat is used for more deteriorated roads. A chip seal treatment can be used to waterproof a pavement just prior to an asphalt overlay. Another effective variation is cape sealing, which applies a chip seal prior to a micro-surface treatment.

The Advantages of Chip Sealing Treatments

- Require minimal corrective-maintenance investment

- Waterproof underlying pavement

- Seal cracks

- Create a new wearing surface

Micro Surfacing

Micro-surfacing treatments use a mixture of polymer-modified asphalt emulsion, 100 percent crushed aggregate, mineral filler, setting additives and water. They provide a new wearing surface to correct raveling and minor cracking and to improve skid resistance. A micro-surfacing seal deposits a uniform wearing surface proportional to surface demand. The application is usually calculated in lbs/square yard and is typically about 3/8-inch thick for a single course.

The Advantages of Micro-Surfacing Treatments

- Provide superior durability for extended service life

- Correct wheel rutting

- Correct moderate pavement bleeding or flushing

- Set and cure quickly, enabling a speedy resumption of traffic

- Minimize curb loss, with no

Conclusion

The three major categories of asphalt surface treatments are fast, effective and affordable. Each serves a specific purpose in the service life cycle of your asphalt roads. Planning preservation enhancements, and applying them during the early stages of pavement life, protects your road department’s investment in capital improvement projects.

Contact us today to discuss your specific needs or call 1-800-333-6309.

For more technical information about these treatment options, visit:

How Asphalt Pavement Preservation and Rejuvenation Saves Money

Category: Blog Articles By: Ken Holton, P.E.

If pavement preservation and maintenance is your responsibility, ponder for a moment:

- What is my goal in managing the pavement asset I am responsible for?

- Am I merely attempting to prolong (at any cost) the time interval between resurfacing cycles?

- Am I attempting to satisfy a political agenda?

- Am I being pressured to implement maintenance activities that I believe will cause complaints from those I serve?

As an engineering professional, when I seek tools from the pavement management toolbox, I look for products and materials that will add value and lower operating costs – solutions with a track record for long-term success in a wide variety of applications. In my former role as a City Engineer, I took this responsibility extremely seriously and found counsel in other professionals in the industry. I knew an effective, full-scale implementation of any maintenance activity would rely not only on my own personal experience, but also on researching and spring-boarding off the success of others who have faced similar challenges.

Early on, I recognized that once a road was resurfaced, it would soon show the initial signs of aging. How could I slow this down? I did not want to resurface this road again in my career if at all possible. So I went on the offense against the cause of asphalt deterioration.

What I discovered was that if a road was structurally sound, I only had to slow the effects of the environment and oxidation. I found that asphalt cement keeps its ductility and flexibility by maintaining the proper maltene/asphaltene balance.1 Reintroducing the natural maltene component of asphalt would slow the effects of the environment on my roads. As I surveyed the roads over time, I witnessed service life extension by several years each time the maltenes were re-introduced to the pavement. I was encouraged to learn, when I spoke with fellow road maintenance professionals, that others were making similar observations.

The 2016 research performed by Joe Vitale and Khalid M. Siddiqi, Ph.D., “The Feasibility of Asphalt Pavement Rejuvenator Applications,” confirmed my own experiences: roadways were aging more slowly when treated with maltene rejuvenation of the asphalt binder. The slower deterioration added eight years of service life! Further, they demonstrated that the longer service life divided by the cost of all maintenance over the longer life provided a 29 percent lower annualized operating cost. This study definitively demonstrated that asphalt pavement rejuvenation saves money!

In effect, replenishing the maltenes holds the roads together from the inside out. The introduction of maltenes makes the asphalt binder more resilient to environmental stresses, binding the entire matrix of aggregates together with better cohesion. This keeps the road surface tight so it actually sheds water faster. All the other environmental factors (UV rays, snow, de-icing treatments, etc.) are similarly kept at bay. The result is a longer lasting, better performing asphalt pavement.

So ponder no longer and do the research yourself: it is possible to have high-performing pavements that last longer while lowering your annualized maintenance costs.